The weighing scale/machine has multiple industrial applications. It plays a vital role in determining the exact measurement of the industries’ things or manufacture. Weighing the goods also helps the companies reduce waste and ensure that they create reliable and consistent products. Regularity in merchandising also improves the efficiency of the packaging and shipping process.

From processing industries to transportation and logistics, weighing scales is essential equipment to optimize utilization and productivity. The global electronic weighing scales market was valued at US$ 4.85 Bn in 2017 and expected to expand at a CAGR of 4.8% during the forecast period from 2018 to 2026. However, choosing the correct weighing scale is not an easy task. Since it plays a significant role in the market, you to assess certain factors before you make your purchase.

If you want to buy a truck weighing machine, you need to check its load-bearing capacity to determine if it is suitable for your business. Measurement of any product or equipment is done with a predefined scale. The companies need to deploy a reliable weighing scale for better precision, accuracy, and repeatability.

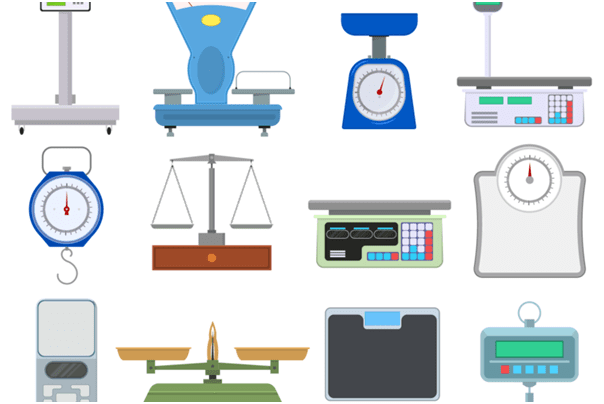

Weighing scales have varied sizes, types, capacities, models, technology, and price. Analyzing your business needs will help you to choose a weighing scale with the required features and specifications. Here are a few pointers that you need to consider while buying a weighing scale.

Requirement

The primary thing which needs to be considered before buying a weighing scale is its applicability and use. You must know where the weighing scale needs to be installed and for what purpose. Assessing your needs will help you to choose appropriate and reliable scales. You can also purchase a tailored solution for easy integration and linearity that will boost productivity.

Analog Or Digital

Analog weighing scales display the weight to the nearest decimal point, while digital scales give an accurate measurement. Analog machines have a simple and straightforward display. A digital weighing scale, however, has an LCD screen display. It has higher functionality and is portable. While analog machines operate with the help of a spring system that may loosen over time, digital scales’ batteries need to be changed regularly to keep them functional. Replacement of batteries is required to keep the frequency stable.

Accuracy

Precise and accurate measurements are a crucial factor while choosing the correct weighing scale. As compared to analog scales, digital scales are suitable for business use as it provides greater accuracy. The responsiveness of the spring of analog scales degrades with time. It may lead to inaccurate results.

Weight Capacity

Weight capacity is an important determinant to buy the correct weighing scale. A buyer needs to determine the weighing scale’s weight capacity, which may range from micrograms to several metric tons.

Display Of Weighing Scale

The display of the weighing machine shows the measurement values in predefined precision. The display can be either single-sided or double-sided, which can allow reading the measurements from both sides. The display is available in seven-segment type or multi-color LED.

Operational Environment

Multiple factors affect the weighing operations of the weighing scale. Errors in the weighing scale can arise from various sources. The magnitude and significance of these errors also depend on the operational environment in which the scales are being used. Hence, this machine needs to be installed in an area free from air currents and away from heating and cooling vents.

In working environments with constant vibrations and mechanical movements, a vibration-proof weighing scale should be installed. In waterlogged working space, waterproof models should be used. The weighing scale should be customized accordingly to operate in the required environment.

Computational Features

The digital weighing scale has automatic operational features. It can turn off when not in use, which helps to save power. Price computational scales, memory retention, and various multifunctional scales find use as per the industrial requirements.

Material Of Weighing Scale

Based on the applicability of the weighing scale, the material used in it differs. In pharmaceutical industries, the weighing scales are compact and have a plastic body with a glass finish. In the grocery department, the scales have plastic/metal bodies to avoid rust. Weighing machines used for bulk loads are fabricated with steel or iron plates for better load retention capacity. It also has an anti-skid base to maintain grip and stability.

To Conclude:

Weighing scales are used for multiple purposes. It is used in manufacturing industries, research and laboratory testing, retail shops, quality assurance, testing, and other varied uses. Depending on the need of the industry, the right weighing scale should be used. The weight-bearing platform of the machine should be adequately strong. Overload indication and auto shut down feature are some of the additional features which you can look for.

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.