CNC laser tube cutting machines are used in the manufacturing industry to cut tubes and pipes with high precision and accuracy. Here we will cover the basics of CNC laser tube cutting machines. Including their working principles, components, applications, and advantages.

Axe and status is one the best options in the UK for buying CNC laser tube cutting machines. Along with that you can also buy heavy machinery and their installation services. Let’s discuss working principles, components and advantages of laser cutting machines.

Working Principles of CNC Laser Tube Cutting Machines

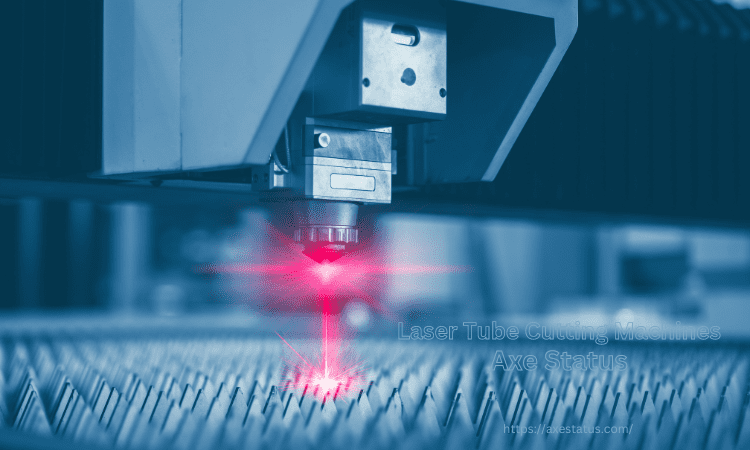

CNC laser tube cutting machines use a laser beam to cut tubes and pipes with high precision and accuracy. The laser beam is focused onto the workpiece, and the heat generated by the laser beam melts or evaporates the material, creating a cut.

CNC laser tube cutting machines are controlled by a computer that uses CAD/CAM software to create the cutting path. The software generates a 3D model of the tube or pipe, and the machine uses this information to cut the material.

Components of CNC Laser Tube Cutting Machines

The main components of a CNC laser tube cutting machine include the laser source. Cutting head, workpiece support system, and control system.

The laser source is the heart of the machine, producing the laser beam that is use to cut the tube or pipe. The cutting head focuses the laser beam onto the workpiece, and the workpiece support system holds the tube or pipe in place during cutting.

The control system includes the computer, software, and interface that are use to program and control the machine.

Applications of CNC Laser Tube Cutting Machines

CNC laser tube cutting machines are use in various industries. Including automotive, aerospace, construction, and furniture manufacturing.

They are ideal for cutting tubes and pipes of different sizes and shapes, including round, square, rectangular, and oval. In the automotive industry, CNC laser tube cutting machines are use to cut exhaust pipes, roll cages, and chassis components.

In the aerospace industry, they are use to cut tubes and pipes for aircraft engines and hydraulic systems. In the construction industry, they are use to cut pipes for HVAC systems and metal frameworks. In the furniture industry, they are use to cut metal tubing for chairs, tables, and other pieces.

Advantages of CNC Laser Tube Cutting Machines

CNC laser tube cutting machines offer several advantages over other cutting methods, including:

High precision and accuracy:

CNC laser tube cutting machines can cut tubes and pipes with high precision and accuracy, resulting in consistent and high-quality cuts.

Fast cutting speed:

CNC laser tube cutting machines can cut tubes and pipes quickly, reducing production time and increasing efficiency.

Versatility:

CNC laser tube cutting machines can cut tubes and pipes of different sizes and shapes, making them ideal for a wide range of applications.

Minimal material waste:

CNC laser tube cutting machines produce minimal material waste, as the laser beam cuts through the material with little or no physical contact.

Automation:

CNC laser tube cutting machines are fully automated, requiring minimal operator intervention and reducing the risk of human error.

Conclusion

CNC laser tube cutting machines are versatile and efficient machines used in the manufacturing industry to cut tubes and pipes with high precision and accuracy. With the right knowledge and training, CNC laser tube cutting machines can be use to produce high-quality parts that meet the needs of various industries.

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.