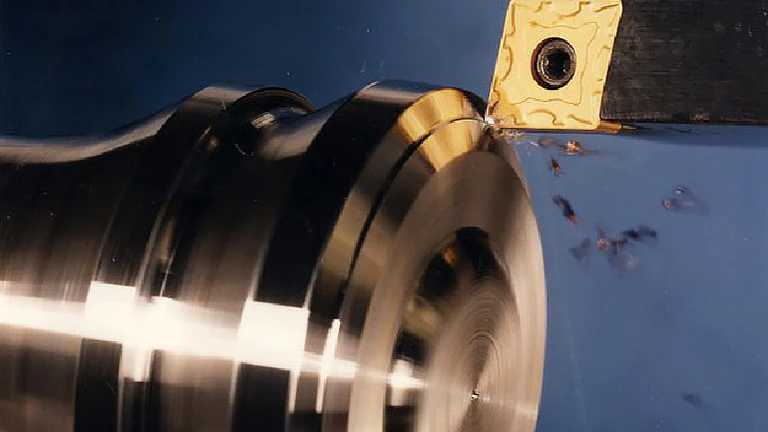

Machining is removing excess material by sawing from a tool in the form of scraps. Such sawing tools are often recognized as cutting tools. Cutting tools are the hard and rigid device that is used to cut and shear off the excess material from the ferrous or non-ferrous metals.

The main aim of a cutting tool is to extract a specific layer of work material. Therefore a cutting tool is a wedge shape and sharp edge device in order to extract material smooth and efficiently that requires minimal power.

Here, In this article, we will discuss different types, classifications, and materials of cutting tools.

What is a cutting tool?

The cutting tool is a blade-type sharp-edged tool. It is used to extract an excess layer of material from the workpiece to get attain the intended form, scale, and quality by shearing metal, wood, plastic, stone, or any other material.

Some cutting tools are mounted and fixed with the machine tools before application and some are non-mounted or hand tools (ready to cut).

- Mounted cutting tools: TCT saw blades (wood, metal, aluminum), Recip blade, spade bits, sanding belts, hole saws, and many more.

- Non-mounted cutting tools or hand tools: Hack saw, hole saws, scissors, knives, hand blades, etc.

Examples of cutting tools

Cutting tools are widely used for cutting or machining ferrous or non-ferrous metals, plastic, concrete, stone, wood, and other hard materials. Different machining processes need different cutting tools or cutters, that’s why there are different tools available on the basis of the application.

Below is the list of the most commonly used cutting tools and their applications.

- Single point turning tool: Turning cutting tools are perfect for turning performed in a lathe operation.

- Drill: Drill bits or drillers are used for the drilling operations.

- Milling cutter: cutting tools for milling operations on milling machines.

- Fly cutter: Cutter for fly milling operations.

- Shaper: Shaper cutters are used to give desired shaper and structure on a workpiece with the help of shaping machines.

- Planer: Planner cutters are used for planning tasks mainly required with the planning machines.

- Boring bar: Boring bar cutter used for boring operation in drilling and boring machines.

- Reamer: Reamer cutters are used for reaming operations in drilling machines.

- Broach: Cutter for broaching operation in the broaching machine.

- Grinding wheel: Grinding wheels are abrasive bonded cutting tools for metal grinding purposes.

Materials of cutting tool

During cutting operations, the cutting tool appears in contact with the workpiece (cutters rotate at high speed that generates heat) and faces high temperatures and scratching. For that cutting tool materials must have the ability to maintain such a high temperature along with cutting efficiency.

So, the cutting tool material must have some specific characteristics, such as higher strength, high heat resistance, high strength, higher melting point, and neutral at high cutting speed. The hardness of the cutting tool material must be 1.5 times the hardness of the workpiece.

To enhance different required properties, the appropriate coating can also be added to the cutting tool. Even then, when the tips are rubbed after extended use, a coated tool does not allow quick re-sharpening by grinding. Nowadays, insert-based cutting tools are also available where it is possible to attach or clip small interchangeable inserts on the large shank.

Some of the commonly used cutting tool materials are:

- High-Speed Steel (HSS)

- Tungsten carbide

- Ceramics

- Cubic Boron Nitride (CBN)

- Diamond

Classification of cutting tool

Cutting tools are mainly classified in three different ways single point and double point and multi-point cutting tools. This differentiation is based on the cutting edges participating in the cutting process.

- Single point cutting tool: Single-point tools have only one main cutting edge that participates in the cutting process. Some examples of single-point cutting tools are turning tools, boring tools, fly cutters, slotting tools, etc.

- Double point cutting tools: Double point tools have two main cutting edges that participate in the cutting process. Examples of double point cutting tools are basic drills, metal cutting drills with two flutes.

- Multi-point cutting tool: Multipoint tools have more than two main cutting edges that cut concurrently. Examples of multi-point cutting tools are milling cutter, broach, gear hobbing cutter, grinding wheel, etc.

Types of Cutting Tools in Workshop

The cutting tool, as the name suggests, is used for the cutting process in various industries. These cutters can be used in different types of machining applications. The cutters have different names based on their specific jobs.

Here is the list of the Commonly used Cutting Tools:

- Air Saw Blades: Air Saw Blades is a heavy-duty saw that cut flat and curved surfaces. These air saws blades are perfect for high-speed metal cuttings.

- Auger Bits: Auger bits have screw tips that quickly bore into wood and twist the whole way down their length to clean the hole and extract as many of the chips and dust that are created as possible while drilling.

- Hack Saws: A hacksaw is a hand tool designed for cutting different materials like rubber, steel, and other hard metals. These bi-metal or trans hacksaws, usually used for cutting wood into small pieces.

- Hole saws: A Bi-Metal Cobalt Hole Saws is used to cut various materials including rubber, steel, and ferrous metals with a standard 4/6 adjustable tooth pitch and 1-1/2? diameter.

- Hole Saw Arbors: Hole Saw arbor is a hand drill that attaches a drill chuck to the individual saw itself. This is mainly defined as a mandrel.

- Recip Blades: Recip Blades are composed of strong materials. For typical uses, the hybrid set offers a variety of blades. For all reciprocal saw models, Metal Reciprocating Saw Blades are functional.

- Spade Bits: Electricians and plumbers typically use spade bits for drilling holes in studs in walls for running wires or pipes.

- TCT Hole Cutter: TCT Hole Cutters are used for cutting metal, wood, and other materials.

- TCT Saw Blades: Tungsten carbides tipped (TCT) blades are built to cut aluminum, wood, steel & other metals. These cutting tools are ideal for Aluminum and Non-Ferrous Metals.

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.