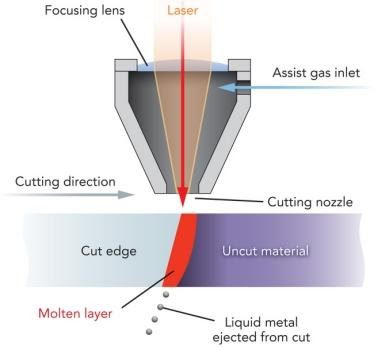

Laser cutting is one kind of thermal cutting, which takes the focused high-power and high-density laser beam to irradiate the workpiece, so that the material at the irradiated place is rapidly melted, vaporized, ablated or reaches the ignition point, and the molten material is removed by a high-speed airflow which is coaxial with the beam to achieve the cutting.

Fig. 1 working principle of laser cutting

1. Methods of laser cutting?

Laser cutting can be roughly divided into four types: namely, vaporization, melt and blow, melt blow and burn, thermal stress cracking,.

1.1vaporization cutting

Figure 2 Laser vaporization cutting

The high-density laser beam is used to heat the workpiece, causing the temperature to rise rapidly to reach the boiling point of the material in a very short period of time, and the material beginning to vaporize to form vapor. These vapors are ejected at a high speed, as the vapors are ejected, a cut is formed in the material. The heat of vaporization of materials is generally large, so Laser vaporization cutting requires a large amount of power and power density.

Laser vaporization cutting is mostly used for cutting very thin metal materials and non-metal materials, such as paper, cloth, wood, plastic, rubber, etc.

The cutting surfaces by vaporization are smooth with no burr.

1.2 Laser melting cutting

1.1.2 Laser melting and blowing

Laser melting and blowing is to use laser heating to melt metal materials, and then sprays high-pressure inert gas (eg. N2, Ar, He, etc.) through a nozzle coaxial with the beam, the strong pressure of the gas removes the liquid metal and forms a slit. Laser melting and blowing do not need to vaporize the metal completely, and the required laser energy is only about one tenth of vaporization cutting.

For thin plate materials, if the cutting speed is too slow, most laser beams will lose energy directly through the incision. Increasing the speed will allow more beams to irradiate the material to increase the coupling power with the material and obtain a wider parameter adjustment area to ensure cutting quality. For thick plate materials, due to laser evaporation or the removal speed of molten products is not fast enough, the beam is reflected multiple times on the cut surface of material. As long as the molten product can be removed before it is condensed by cold air, the cutting process will continue.

The edges of the laser melting and blowing take the from of strips.

Laser melting and blowing is mainly used for cutting of non-oxidizable materials or active metals, such as stainless steel, stainless iron, titanium alloy, aluminum, etc. Laser melting and blowing uses nitrogen as auxiliary gas for cutting, the cost is higher than oxygen cutting.

The Fiber laser CNC laser cutter is use this method to cut metal.

1.3.oxygen-assisted melting and burning

The principle of laser oxygen-assisted melting and burning is similar to oxyacetylene cutting. It uses laser as preheating heat source and oxygen as auxiliary cutting gas. The sprayed oxygen produces a chemical reaction with the iron element which is heated to about 1500 ? C by the laser, thereby continuing to emit a large amount of oxidizing heat, and the iron element is heated and burned; on the other hand, the molten liquid oxide and the melt are removed from the reaction zone by airflow to form a cut in the metal. As the oxidation reaction in the cutting process generates a lot of heat, the energy required for laser oxygen cutting is only 1/2 of melting and blowing, and the cutting speed is much faster than laser vaporization cutting and melting cutting.

The edge roughness of laser oxygen-assisted melting burning is between laser vaporization cutting and laser melting cutting.

Laser oxygen-assisted melting burning is mainly used with carbon steel and other easily oxidizable metal materials. It can also be used for cutting of stainless steel and other materials, however, the section is black and rough, and the running cost is lower than inert gas cutting.

1.4.Thermal stress cracking

The brittle material which is easily damaged can be cut by high-speed and controllable laser beam, this kind of laser cutting is called Thermal stress cracking. The cutting principle is: the laser beam heats the small area of the brittle material, causing thermal gradients and the subsequent severe mechanical deformation, which causes the material to form cracks. The speed of thermal stress cracking is fast, requiring only a small laser power; too high power will cause the workpiece surface to melt and damage the cutting edge. The main controllable parameters for thermal stress cracking are laser power and spot size.

2.Features of laser cutting

Compared with other cutting methods, laser cutting is mainly characterized of fast cutting speed and high quality as follows:

2.1. Good cutting quality. Owing to the small laser spot, high energy density and high cutting speed, the laser cutting can obtain better cutting quality.

2.2. The slit by laser cutting is narrow, the two sides of slit are parallel and the perpendicularity to the surface is good.

2.3. The cutting surface is smooth and beautiful, the parts can be used directly, further process is not required.

2.4.the width of heat-affected zone after cutting is very small, the performance of the material near the slit is hardly affected, the deformation of the workpiece is small and the cutting accuracy is high.

2.5.High cutting speed, for example: the cutting speed of 1mm cold-rolled carbon steel plate by 2500 W laser cutting can reach 16 – 19 m / min.

2.6. Non-contact cutting, the nozzle is not in contact with the workpiece during laser cutting, and there is no tool wear.

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.