When people talk about waste reduction, plastic waste steals all the headlines. Sure, plastic waste is extremely harmful, but it isn?t the only problem. The amount of electronic waste that?s currently overwhelming landfills across the world is staggering. Before they contaminate our soil and water to the point of no return, companies, and consumers must change their attitudes towards e-waste.

A Major Waste Problem

In just 2019, 53.6 million metric tons of e-waste was created across the world. That?s a 21% increase in e-waste since 2015. If we continue at this rate, global e-waste will amount to 74 million metric tons in 2030. In less than seventeen years, we will have doubled the amount of e-waste we generate, making it the world?s fastest expanding domestic waste stream. This implausible increase in e-waste is fueled not just by our collective desire to consume more electric and electronic devices but also our desire to discard electric and electronic equipment as soon as there?s one repair requirement.

Short life-cycles of products and the reluctance of companies and consumers to spend on equipment repairs will lead to dangerous levels of waste production. Given that only 41 countries share their official e-waste statistics with the UN?s next Global E-Waste Monitor, the e-waste problem may be bigger than we think it is.

Repairs Are the Answer

What are leading OEMs and electronic companies doing to tackle the e-waste problem? Very little. Some positive steps include Apple?s decision to slow down models as they age so that people upgrade or repair their phones. Other manufacturing companies like Sonos are being forced to issue software updates for their older models to increase product life-cycles.

Overall, most companies are not over-committed to aiding this fight against e-waste. Hence, investors and consumers need to be aware of this significant and growing issue and hit the manufacturing companies where it hurts them the most ? their reputation. If more consumers start investing in electric equipment repairs instead of buying new devices, the changes in the amount of e-waste we produce could be astronomical.

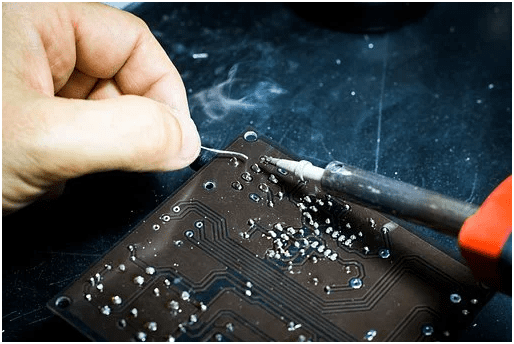

One of the electronics components that contribute heavily contribute to the amount of e-waste we create is the printed circuit board (PCB). PCBs are often at the root of most electronic device failures. Unfortunately, most consumers don?t know how successful PCB repair techniques are.

That?s why manufacturers are more than happy to discard PCBs when they fail. Both retail and institutional level investments in PCB repair services can help us win this battle against e-waste. But for such a drastic change to happen, people first need to understand why investing in PCB repairs is far better than replacing malfunctioning electronic equipment.

Repair vs. Replace

The repair versus replace debate in the electronics assembly industry is very ugly. Unfortunately, large-scale and ever-increasing investments in consumer electronics technology mean that electronic devices don?t need to survive for five years, let alone ten years.

If PCBs fail prematurely, super-rich electronics manufacturing companies simply order new ones. Similarly, consumers who don?t know about the effectiveness of PCB troubleshooting and repair services prefer to invest in new products.

This skewed outlook on PCB repairs costs companies, consumers, and the environment. Did you know, by repairing your electronic device?s PCB, you can save up to 70% of what it would cost you to buy a new product? Saving money and fighting the e-waste crisis that our planet is facing ? there?s no reason to prefer replacing over repairs!

Finding Affordable PCB Board Repair

Contrary to popular belief, the cost of Printed Circuit Board repair is far less than buying new devices. Top PCB repair experts are more than happy to save their clients? money by preventing them from getting super-expensive upgrades. Yes, the electronics industry is constantly evolving, and there are legitimate reasons for professionals and students to upgrade their devices from time to time.

But, replacing every product at the first sign of improper functioning is a really bad habit that most consumers are guilty of. Plus, there are easy ways to find cost-effective PCB board repair services. A high-quality and affordable PCB repair expert can restore minor or major faults in your electronics equipment with speed and precision. Here?s how consumers must approach PCB repair services to cut costs –

Understand the Repair Requirements

Consumers need to understand what type of repair work their products need. They need to assess the different repair and replace options before making a decision. For instance, troubleshooting for significant component failures doesn?t cost as much as buying a brand-new product. But, completely reworking a faulty device can be costlier than buying a new one.

Investing in Troubleshooting

Troubleshooting is a process where PCB repair experts detect and locate underlying problems with electronic components. In most cases, small issues like broken firing or malfunctioning components cause electronic devices to fail. These processes don?t cost much, and if you?re lucky, a simple replacement will save you expensive upgrades.

The first step to becoming conscious consumers of electronics products is understanding your repair requirements. The more information a consumer has about the problem in their electronic device, the more money they can save. So, find a reliable PCB repair expert and start tackling this issue of increasing e-waste!

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.