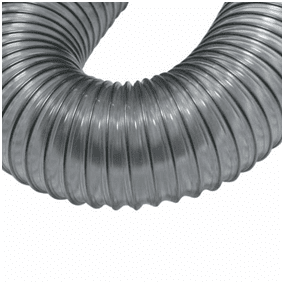

A flexible hose is, quite simply, a hollow tube designed to transport gases and fluids from one place to another, such as chemicals, water, steam, and air. You probably have never thought about them much before; let’s face it, they’re not the most thrilling of all consumer products. However, they are efficient and can be used in various industries for a wide variety of different applications. It is necessary to do your homework first if you need to Purchase Flexible Hose In India for your exact specifications and needs.

There is more to industrial hoses than a flexible, reinforced tube. They are the center of your service, acting as transfer lines in today’s major industries for various applications. Every industry has its own unique needs, and it is important to choose the correct type of hose, from material to size, for your operation to run smoothly.

Thinking about purchasing a flexible hose

You can quickly learn that it is not just a one-size-fits-all scenario when you think to Purchase Flexible Hose In India. Flexible hoses are developed and produced for a wide variety of different uses by leading manufacturers. This means that some hoses are specifically made for a particular application, while others do not work as well as possible if they are not used for the right purpose.

Flexible hoses are used in the chemical industry to transport solvents, acids, and fuel from water and air, asphalt, dust, and dirt, and are also used in the food industry to hold several different types of meats, fats, oils, and air.

A flexible hose is a kind of industrial hose. In order to transfer fluid from one substance to another, and the industrial hose is something that is used. In hydraulic and other process applications, it is also important. In heavy industries, including construction and mining, some of its most unusual applications are seen. Generally speaking, an industrial hose is defined as versatile.

It pays to look at its implementations to learn more about the idea of a versatile hose. For the use of this industrial product, there are general as well as particular categories. The reasons for each of these applications are given below.

General and specific applications

There are general and particular applications for this type of industrial house, as stated a while back. Woodworking or the collection and filtration of dust is one example. In order to complete the design of the dust collector, the hose is used and is specifically helpful in accumulating dust and small chips. The flexible hose is used by both industrial and home shops geared specifically to woodworking.

Another general use is leaf collection and lawn vacuum for this industrial hose. At times, without a lawn mower’s help, it would not be easy to sweep the lawn. It makes lawn mowing simple with the hose. Although the hose is usually described as flexible, it is durable. It is said to be suitable for detecting blockages of leaves, sticks, or debris in a building or residential area.

Of course, the use of a flex hose often benefits from metalwork. Oil mist is conveyed by the use of this material in machining centers. The hose is also relatively important for fume control as it facilitates the elimination of fumes accumulated in internal spaces.

Additional Applications

Materials handling is the most common of all industrial applications for the flex hose. The commodity is used for all general purposes in this field, from agricultural, chemical, landscaping, and HVAC systems to aviation and aerospace, medical or pharmaceutical, food and beverage processing, and marine industries.

Each flexible hose is produced in these industries according to what actually concerns the particular region. For example, the hose is manufactured in the medical sector to provide safer options for products used in the health care industry. Other products can also be produced, apart from medical hoses manufactured for this field. The real point is that until the client decides what he needs and wants out of the end product, a flex hose is not done.

Tested and Inspected

It is imperative to get your hoses inspected and checked periodically, no matter what sort of hose you need for your project or job. Before each application, hoses and couplings should be inspected, especially when dealing with hazardous chemicals.

To make sure there are no holes, scratches, abrasions, exposed reinforcement, or blisters, you can visually check your hose regularly. Other more intensive studies, such as chemical testing or bonds between fittings, should be conducted by experts.

Hoses are a vital component of the proper operation of many industries. For the movement of chemicals, gasoline, power, air, water, bulk materials, and water suction and discharge, industrial hoses are used. It’s necessary to Purchase Flexible Hose In India to transfer materials for your project. It can be disastrous to pick the wrong hose. Your image can be destroyed by the wrong material and pressure rating and even cause injuries.

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.