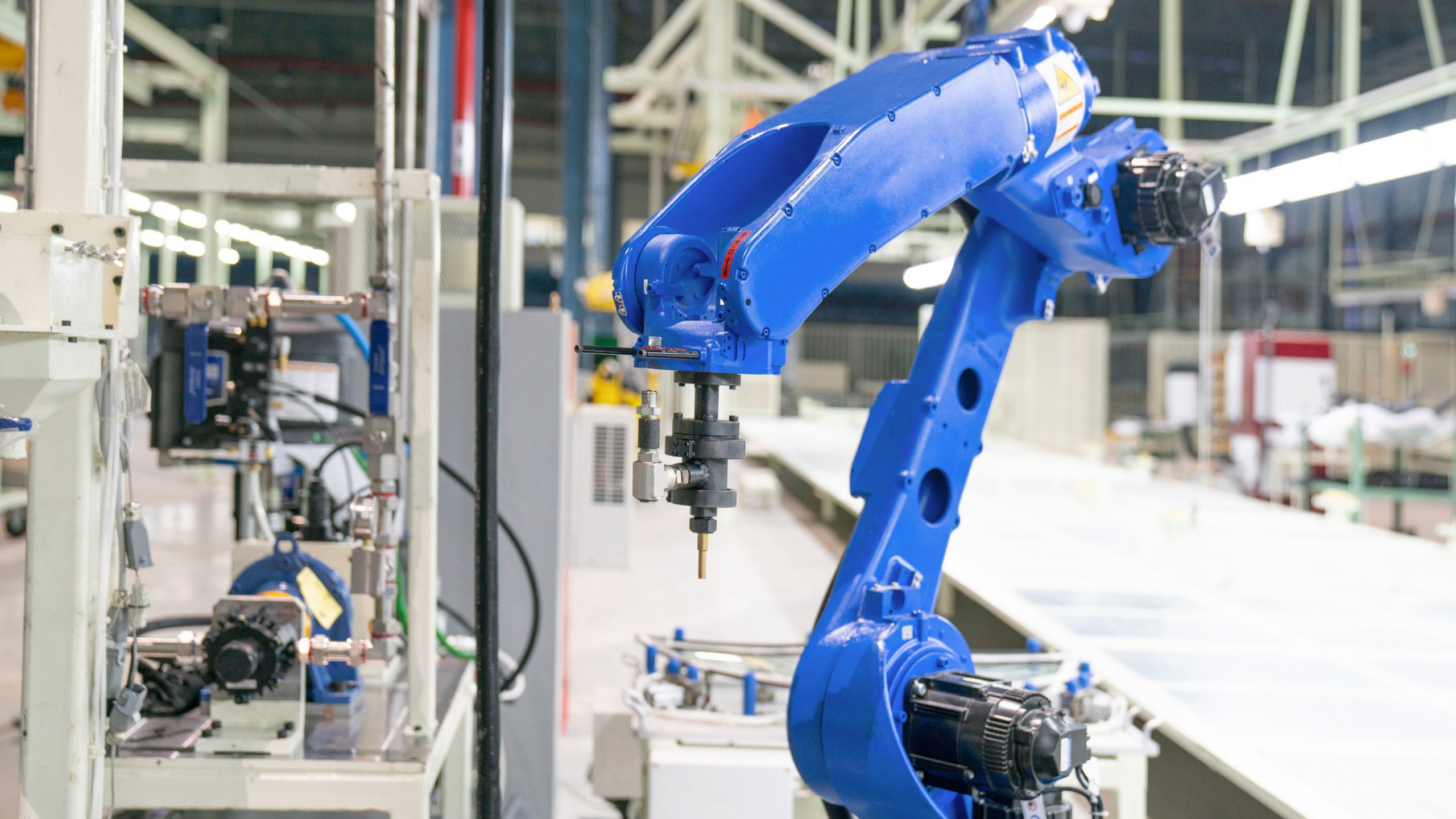

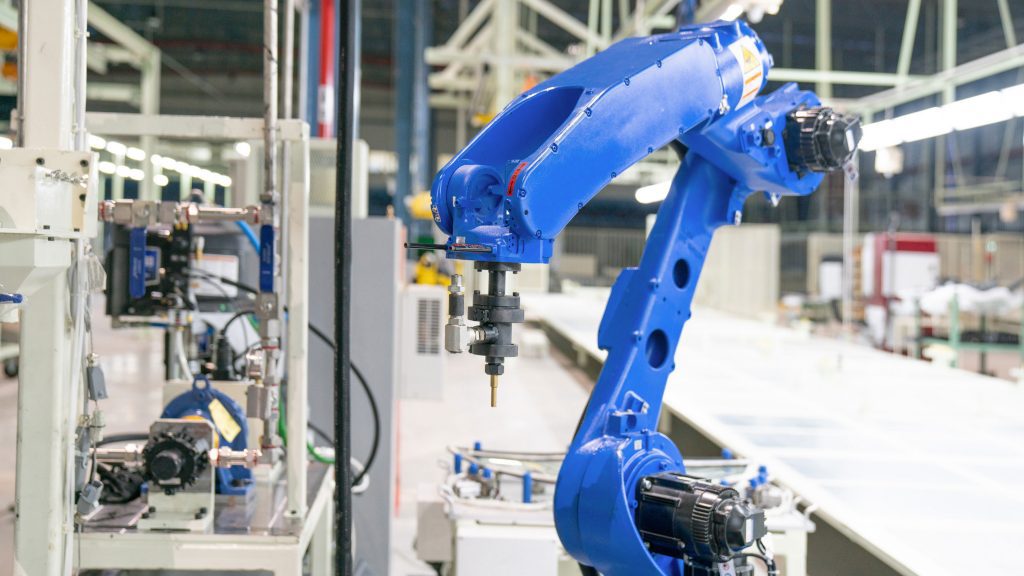

Robotic systems vary in size and degree of integration with each other. Let’s start our acquaintance with industrial robot systems with the smallest robotization unit – with a robotic site. A robotic section is two or more robotic cells that are technologically connected. These robotic cells can work sequentially or in parallel, the main thing here is work within a relatively isolated technological process. It is the isolation of the operations performed that allows you to combine this set of robotic cells into a robotic section.

Robotic lines are a more complex system of industrial robots and auxiliary lines synchronized to perform a series of sequential operations, most often within a production line. The connecting element between robotic cells within a robotic line is conveyor systems of varying complexity. In rare cases, the transfer of workpieces from robot to robot is configured.

The use of robotic lines as a solution for production automation has a number of undeniable advantages, the main one of which is their flexibility. Despite the apparent rigidity of the adopted technological scheme, the robotic line is easily reconfigured for the production of new products when the control program is changed. Robots as part of automated lines do not require complex part positioning systems, which is mandatory when creating automated solutions based on automatic and semi-automatic machines.

Any production process in today’s enterprise can be outsourced to robotic systems. First of all, these are welding, painting and assembly operations, palletizing of finished products. To a lesser extent, operations of milling, drilling, cutting, etc.

Stages of implementation of robotic systems

The implementation of robotic systems always goes through a series of successive stages. Let’s consider each of them. Please note that the sequence presented here is largely arbitrary and the work on the implementation of industrial robot systems is complex.

The first stage of robotization of production – preparation and optimization of production

Preparation and optimization of production for the implementation of a robotic system includes replacing manual equipment with semi-automatic or automatic equipment of appropriate performance, designing conveyor lines for supplying blanks and removing finished products, checking electricity supply systems, if necessary, compressed air. It is also necessary to prepare warehouses for receiving finished products. The implemented robotic system will most often not be the first in the technological process, but will receive blanks and semi-finished products from other machines, therefore, the interconnection of the productivity of the machines before and after the robotic cell is required.

Ideally, at this stage, a project for complex robotization and automation of all technological operations is being developed, but in practice this is extremely rare. More often, the introduction of robotic systems is carried out in parts by installing individual robotic systems.

The second stage is the selection of a company that produces industrial robots. At this stage, robotization turns into a practical channel. Since the specific technical solutions and the choice of the contractor will depend on this, i.e. integrator. Industrial robot integrators rarely work with several brands of industrial robots at the same time. It is often difficult to separate these two stages and often they go simultaneously. Of course, we recommend, as soon as you think about the introduction of robotic systems in your enterprise, immediately contact a system integrator, for example, our company’s specialists, then we will develop preparatory measures and select equipment with an eye to the robots that we will install …

Of course, the first option also has a right to exist. Very often we come across it when the customer has already done something and asks us to install robots. More often than not, we embed our solutions into the existing technology. But sometimes you have to make some changes in other production areas.

Finally, Industrial Robot Palletizer Is the best option for you.

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.