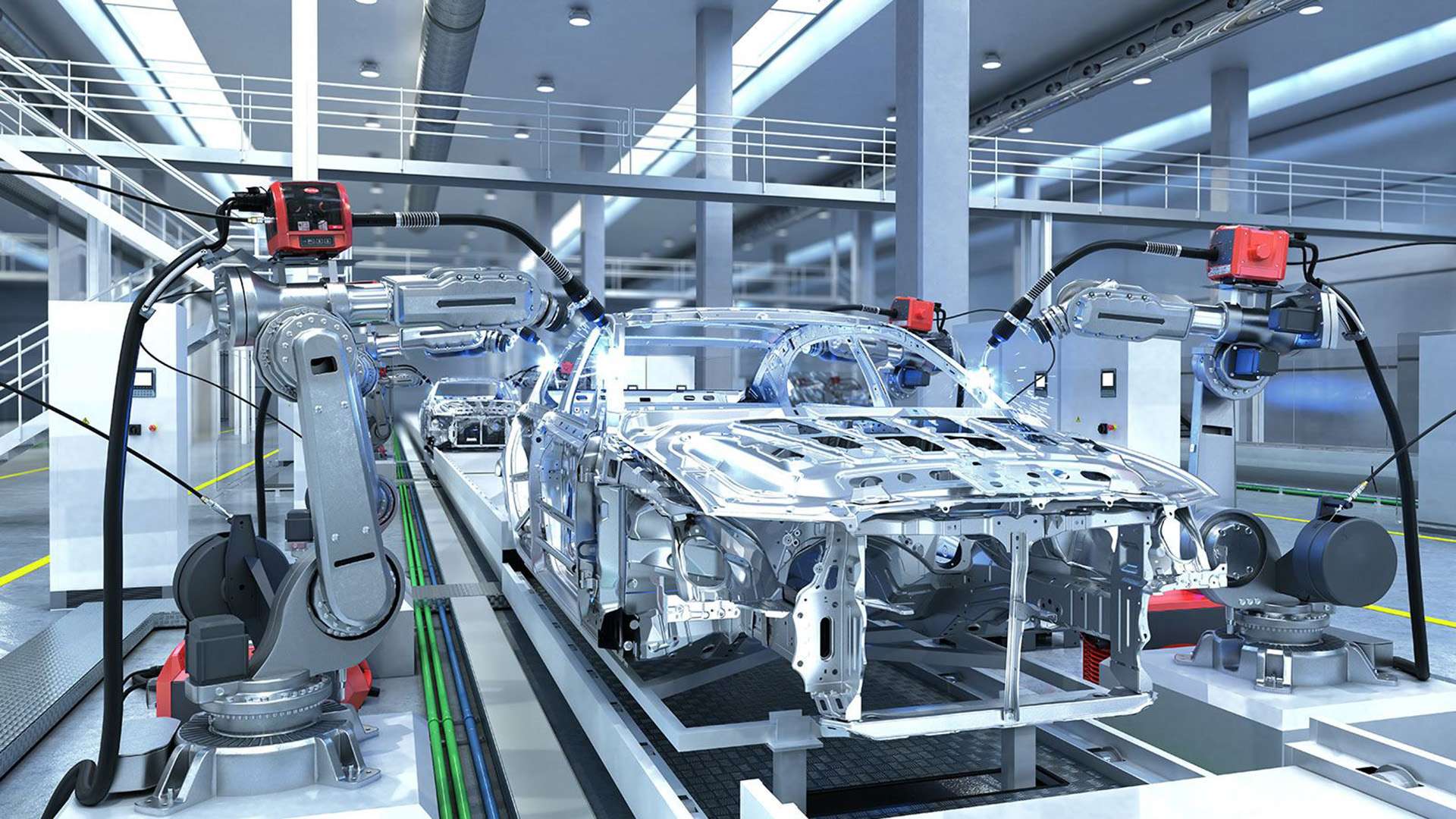

When building high-performance vehicles, many different materials and parts are utilized to ensure that the car operates at its highest potential. One such component is the 455 stainless steel round bar. This material has been used in the automotive industry for many years, and with good reason. In this blog post, we will explore the different uses of 455 stainless steel round bars in the automotive industry and why it is a crucial part of vehicle manufacturing.

What are 455 stainless steel round bars?

455 stainless steel round bars are cylindrical metal rods made from 455 stainless steel, precipitation-hardening stainless steel. This alloy is known for its high strength, corrosion resistance, and durability, making it a popular choice in various industries, including aerospace, automotive, medical, and more. 455 stainless steel round bars are produced through hot rolling, cold rolling, or drawing. They are typically available in a range of diameters, allowing them to be used in various applications. They are commonly used when a combination of strength and resistance to corrosion and high temperatures is required.

Uses of 455 stainless steel round bars in the automotive industry

Superior Corrosion Resistance

One of the key benefits of using 455 stainless steel round bars in the automotive industry is its superior corrosion resistance. This material can withstand harsh weather conditions and exposure to water, salt, and other corrosive elements that can cause metal parts to rust and degrade over time. By implementing this material into the manufacturing process, car makers can ensure their vehicles can last longer and perform better overall.

High Strength-to-Weight Ratio

455 stainless steel round bar is also highly sought for its high strength-to-weight ratio. It is particularly important in the automotive industry, where every pound added to a car can have a significant impact on its performance and fuel efficiency. By incorporating this material into the chassis, suspension, and other key areas of the car, manufacturers can build fast, lightweight cars capable of reaching high speeds while remaining agile and responsive.

Excellent Ductility

Another unique characteristic of the 455 stainless steel round bar is its flexibility. Ductility refers to the ability of a material to bend and flex without breaking or cracking. In automotive applications, bending or shaping parts to fit specific spaces is particularly important. With its high flexibility, the 455 stainless steel round bar can be shaped and formed into almost any shape or configuration, making it an extremely versatile material.

Resistant to High Temperatures

Finally, the 455 stainless steel round bar is also highly resistant to high temperatures. This quality renders it an excellent material for application in engines, exhaust systems, and other car components subjected to high temperatures. By using this material, carmakers can ensure that their vehicles can operate efficiently and safely, even under harsh driving conditions.

Conclusion:

There is no denying the important role that 455 stainless steel round bar plays in the automotive industry. Its unique blend of strength, flexibility, and corrosion resistance makes it an ideal material for various car components. Whether used in suspension systems, exhaust pipes, or steering columns, this material is a key part of the modern vehicle. As technology advances and cars become even more complex, we will see an even greater demand for this versatile material in the future.

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.