In the realm of manufacturing, ensuring quality is paramount to success. This rings especially true in industries like resin plant manufacturing, where precision and reliability are essential for delivering products that meet stringent standards. Quality assurance (QA) practices play a pivotal role in the entire manufacturing process, dictating not only the calibre of the final product but also the reputation and longevity of the company itself.

Understanding Quality Assurance in Resin Plant Manufacturing

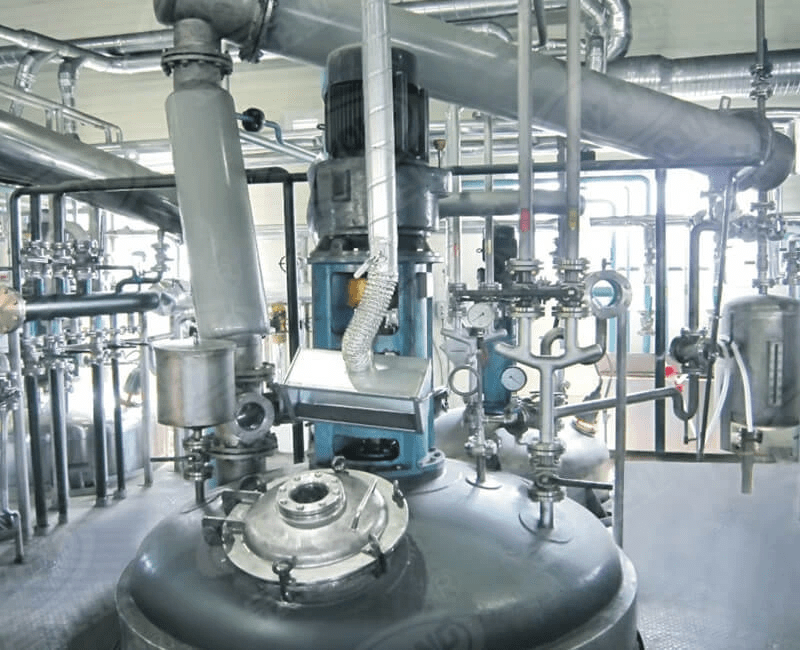

Resin plant manufacturers are tasked with producing equipment that is capable of efficiently and consistently synthesising various types of resins. These resins serve as fundamental components in countless applications, ranging from adhesives and coatings to plastics and composites. Given the diverse array of industries reliant on resin-based products, the stakes for quality in resin plant manufacturing are undeniably high.

Importance of Quality Assurance

- Consistency: QA processes ensure that resin plants operate with precision and uniformity, resulting in consistent output quality. This consistency is crucial for downstream processes that rely on predictable resin properties.

- Compliance: Adherence to regulatory standards and industry specifications is non-negotiable in resin manufacturing. QA protocols ensure that resin plants meet or exceed these requirements, mitigating risks associated with non-compliance.

- Customer Satisfaction: High-quality resin plants translate to high-quality resin products. By prioritising QA, manufacturers can foster customer trust and satisfaction, leading to repeat business and positive brand reputation.

- Cost Efficiency: Investing in QA upfront can yield significant cost savings in the long run by minimising defects, rework, and recalls. Furthermore, efficient QA practices optimise resource utilisation, enhancing overall operational efficiency.

The Role of Advance Biofuel in Quality Assurance

Advance Biofuel is a leading provider of cutting-edge solutions in resin plant manufacturing. With a steadfast commitment to quality assurance, Advance Biofuel has established itself as a trusted partner for industries reliant on resin-based materials. Leveraging state-of-the-art technology and industry expertise, Advance Biofuel integrates robust QA processes at every stage of manufacturing, ensuring unrivalled performance and reliability in its resin plant offerings.

Advance Biofuel’s Quality Assurance Approach

At Advance Biofuel, quality assurance is not merely a checkbox but a cornerstone of our operations. We employ a comprehensive approach to QA encompassing the following key elements:

Rigorous Testing Protocols

Before any resin plant leaves our facility, it undergoes rigorous testing against predefined performance criteria. This includes functional tests, stress tests, and reliability assessments to validate operational integrity under various conditions.

Continuous Improvement Initiatives

We believe in continually raising the bar for quality. Through ongoing monitoring, feedback analysis, and process optimization, we identify areas for enhancement and implement proactive measures to elevate the quality of our products continually.

Compliance Adherence

Advance Biofuel is committed to upholding the highest standards of regulatory compliance. Our QA practices align with industry regulations and standards, ensuring that our resin plants meet or exceed all requisite criteria for safety, performance, and environmental responsibility.

Customer-Centric Focus

We actively engage with our clients to understand their unique requirements and tailor our QA processes to deliver solutions that exceed expectations. Our dedication to customer-centricity fosters long-lasting partnerships built on trust and mutual success.

Quality Assurance: The Key to Success for Resin Plant Manufacturers

In the realm of manufacturing, especially in industries like resin production, maintaining high standards of quality is paramount for success. Resin plants play a crucial role in various sectors, including automotive, construction, and electronics. As such, ensuring that these plants adhere to rigorous quality assurance measures is imperative not only for the manufacturer’s reputation but also for meeting the demands of discerning customers.

Why Quality Assurance Matters

Quality assurance encompasses a set of systematic activities that ensure products meet specified requirements and standards. For resin plant manufacturer, this means adhering to stringent quality control protocols throughout the production process. From raw material sourcing to final product testing, every stage must be meticulously monitored to uphold the highest quality standards.

Advance Biofuel: Leading the Way in Resin Plant Manufacturing

At Advance Biofuel, we understand the critical role that quality assurance plays in resin plant manufacturing. As a leading manufacturer in the industry, we have established ourselves as pioneers in delivering top-notch products that exceed customer expectations. Our commitment to quality is evident in every aspect of our operations, making us a trusted partner for businesses worldwide.

Our Commitment to Excellence

At Advance Biofuel, we prioritise excellence in everything we do. From the selection of premium raw materials to the implementation of cutting-edge manufacturing processes, we spare no effort in ensuring that our resin plants meet the highest quality standards. Our relentless pursuit of excellence has earned us a reputation for reliability and integrity in the industry.

Stringent Quality Control Measures

Quality assurance begins with stringent quality control measures. At Advance Biofuel, we have implemented robust quality control protocols at every stage of the manufacturing process. This includes thorough inspections of raw materials, precise monitoring of production parameters, and comprehensive testing of the final products. By adhering to these measures, we can guarantee the consistency and reliability of our resin plants.

Continuous Improvement

In addition to maintaining high-quality standards, we are committed to continuous improvement. At Advance Biofuel, we regularly review and refine our processes to incorporate the latest advancements in technology and industry best practices. By embracing innovation and adaptability, we ensure that our resin plants remain at the forefront of the industry, delivering unmatched performance and reliability to our customers.

Customer Satisfaction

Ultimately, our dedication to quality assurance is driven by a commitment to customer satisfaction. We understand that our success is measured by the success of our customers, which is why we go above and beyond to deliver products that meet their exacting standards. Whether it’s providing personalised solutions or offering ongoing support and maintenance, we strive to exceed customer expectations at every turn.

Conclusion

In the competitive landscape of resin plant manufacturing, quality assurance emerges as the cornerstone of success. Manufacturers like Advance Biofuel recognize the importance of upholding stringent quality standards to deliver products that inspire confidence and trust. By prioritising excellence, implementing rigorous quality control measures, and embracing continuous improvement, companies can position themselves as industry leaders and forge lasting partnerships with customers around the globe.

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.