Introduction

In recent times, the emergence of Industry 4.0 has initiated a fresh phase of technological progress and ingenuity, revolutionizing the landscape of the manufacturing sector. This fourth industrial revolution, characterized by the assimilation of cyber-physical systems, data analysis, and automation, has paved the way for unparalleled levels of effectiveness, productivity, and interconnectedness. Within this guest post, we will delve into the historical context of Industry 4.0, investigate its advantages and challenges, explore emerging trends and future prospects, and ultimately acknowledge its transformative potential.

Background on the Industry 4.0

Industry 4.0 represents a significant advancement over past industrial revolutions, leveraging cutting-edge technologies such as the Internet of Things (IoT), artificial intelligence (AI), cloud computing, and big data analytics. By seamlessly merging machines, systems, and humans, this revolutionary transition enables the instantaneous flow of data, intelligent decision-making, and self-governing operations. It empowers manufacturers to enhance their processes, streamline supply chains, and deliver personalized products with remarkable precision and efficacy.

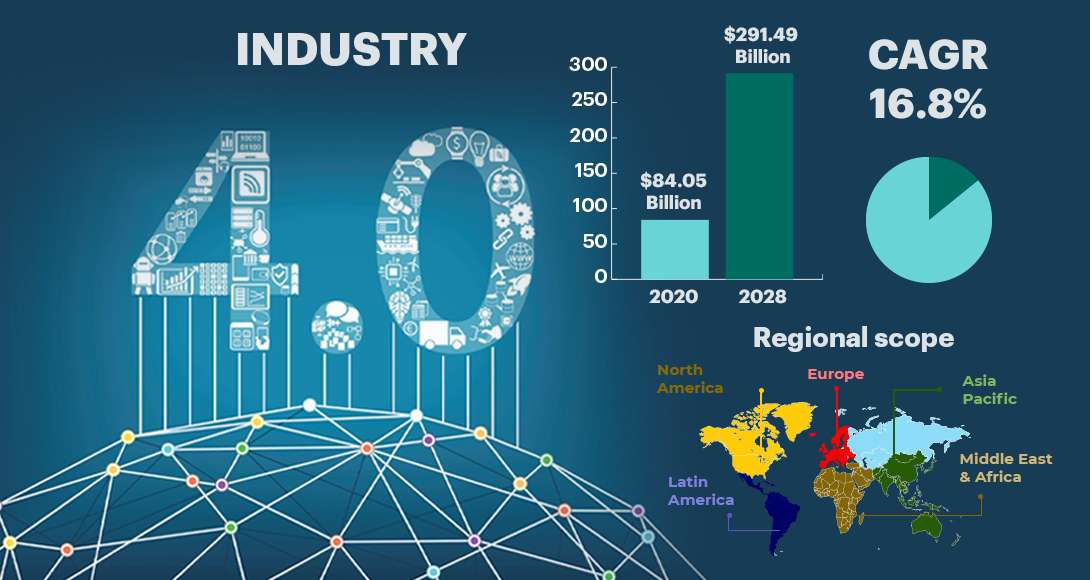

Insights into the Market

Reports and Data has predicted that Industry 4.0 market is expected to be worth USD 291.49 Billion by 2028, increasing at an 16.8% CAGR during the forecast period. The steady growth of revenue in the industry 4.0 market is propelled by several compelling factors. One significant factor is the remarkable shift towards industrial automation and the widespread deployment of robots across various manufacturing processes and industries. The increased utilization of robot technology, coupled with the rising investments by governments in digitalization initiatives, further fuels the momentum towards embracing Industry 4.0.

The major players in the Industry 4.0 market are Mitsubishi Electric Corp., ABB Ltd., Microsoft Corporation, Cisco Systems, Inc., General Electric Company, KUKA, Yaskawa, FANUC, Google, and Intel Corporation.

Benefits of Industry 4.0

Industry 4.0 brings forth a multitude of compelling advantages that leave a lasting impact. To begin with, it initiates a revolutionary transformation in production capabilities through the introduction of “smart factories.” These cutting-edge, digitally integrated environments harness the power of interconnected systems, facilitating seamless resource allocation, predictive maintenance, and real-time monitoring. Consequently, manufacturers can attain unprecedented levels of productivity, minimize costly downtimes, and elevate the overall quality of their products. This transformative shift empowers businesses to unlock unparalleled efficiency and optimize their operations to stay ahead in today’s dynamic market.

Also, the Industry 4.0 plays a pivotal role in nurturing the advancement of intelligent merchandise. By incorporating embedded sensors and seamless connectivity, products transcend their mere physical existence, transforming into astute entities empowered to gather valuable data, establish communication with other devices, and deliver personalized encounters. This dynamic shift unlocks fresh opportunities for engaging customers, driving product innovation, and generating enhanced value.

In addition, Industry 4.0 propels progress in data analytics and predictive modeling. The large amount of data generated in real time by interconnected devices enables precise predictions, streamlined inventory management, and proactive decision-making. Through the utilization of big data and AI, manufacturers can enhance production processes, reduce waste, and improve resource efficiency.

Challenges and Concerns

Although Industry 4.0 offers numerous opportunities, it also introduces certain challenges that must be tackled. An important challenge is the requirement for a competent workforce capable of effectively utilizing and overseeing the intricate technologies involved. The integration of AI, IoT, and automation necessitates a workforce that can collaborate with machines, analyze extensive data sets, and adapt to quickly evolving technologies. Closing this skills gap is essential for the successful implementation and acceptance of Industry 4.0.

Another challenge arises in guaranteeing the security and privacy of interconnected systems and data. As connectivity expands, so does the vulnerability to cyber threats and data breaches. Manufacturers must allocate resources towards robust cybersecurity measures, adopt secure communication protocols, and establish stringent data protection frameworks to safeguard crucial information.

Emerging Trends & Future Prospects

As Industry 4.0 progresses, several emerging trends are influencing its direction. One notable trend is the growing prominence of edge computing, which involves processing data in proximity to its source. This reduces latency, enhances real-time decision-making capabilities, and follows a decentralized approach. Edge computing enables quicker response times, enhances data privacy, and decreases bandwidth requirements.

Another significant trend is the convergence of the physical and digital domains, commonly known as “cyber-physical systems.” This convergence blurs the boundaries between the physical and virtual worlds, facilitating real-time monitoring, digital twinning, and remote control. Manufacturers can create digital replicas of physical assets, allowing for the simulation and optimization of processes, resulting in enhanced efficiency and cost reduction.

In terms of future prospects, Industry 4.0 is positioned to revolutionize not just manufacturing but also various sectors like healthcare, logistics, and agriculture. The incorporation of intelligent systems and data-driven decision-making will open doors to personalized medicine, streamlined supply chains, and sustainable farming practices. The transformative impact of Industry 4.0 extends beyond manufacturing, propelling society towards a more interconnected and technologically advanced future.

Conclusion

Industry 4.0 signifies a significant shift in manufacturing, bringing forth a wide range of advantages alongside distinct challenges. The incorporation of cyber-physical systems, data analytics, and automation has transformed production capabilities, empowered intelligent products, and facilitated data-driven decision-making. However, it is crucial to address the skills gap and ensure cybersecurity measures are in place. With emerging trends like edge computing and the convergence of physical and digital domains, Industry 4.0 is set to reshape industries and unlock new opportunities. As we embrace this fourth industrial revolution, collaboration, innovation, and adaptability will be key in harnessing its transformative potential and realizing a future driven by technology.

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.