A compressor is a mechanical gadget that builds the weight of gas by lessening its volume. An air blower is a particular sort of gas blower.

Compressors are similar to pumps: both press a liquid and both can move the liquid through a pipe. As gases are compressible, the blower likewise decreases the volume of a gas. Fluids are moderately incompressible; while some can be compacted, the fundamental activity of a siphon is to pressurize and ship fluids. Festo compressors are the best to use.

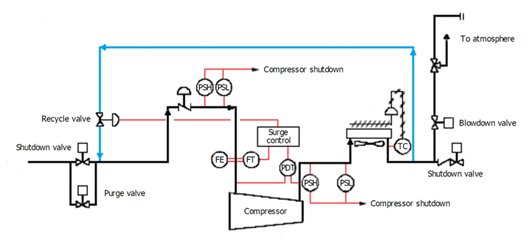

The Instrumentation in a Compressor Includes :

- Weight Transmitters.

- Temperature Transmitters

- Gas Detectors ( if there should be an occurrence of gas spillage)

- Fire indicators ( incase of Fire)

- Level Switches ( to keep up the best possible grease. On the off chance that the oil level or coolant level is low it will send a sign to the processor)

- Stream switch ( If there is no progression of Oil or coolant because of spillage or some other blockage)

- Flow transmitter.

The sign from the above instruments is sent to the processor. the processor at that point sends a controlling sign to curls that work the actuators and valves. The processor is interfaced with a power meter to screen the electrical parameters. HMI is interfaced with the Processor to show the readings of temperature, pressure, stream. it can likewise show the status of the oil level and coolant level.

An instrument air controller controls the use of air for working valves in pneumatic instruments. Valves are process control hardware for modern instruments and instrument air blowers guarantee that the air going through to control these procedure control gear is of the right weight and temperature.

Compacted air is commonly going through aftercooler, dampness trap, radiator and alumina air dryer(adsorption type) with the goal that its dew point is controlled in the scope of – 50-degree centigrades. I intend to state no dampness. This is basic for all the air-activated instruments.

A similar air is circulated to the instrument header and administration air header. Since the control frameworks are extremely crucial for any concoction, pharmaceutical businesses, separation of instrument air and procedure air are fundamental. Instrument air is the air framework utilized in the working pneumatic instrument valve. the structure included more security highlights.

About Air Compressor –

By one of a few strategies, a compressor powers increasingly more air into a capacity tank, expanding the weight. At the point when tank pressure arrives at its designed maximum farthest point, the air blower stops. The packed air, at that point, is held in the tank until called into utilization.

The vitality contained in the packed air can be utilized for an assortment of uses, using the motor vitality of the air as it is discharged and the tank depressurizes. At the point when tank pressure arrives at its lower limit, the air compressor turns on again and re-pressurizes the tank. An air blower must be separated from a siphon since it works for any gas/air, while siphons chip away at a fluid. Festo India provides all types of compressors.

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.